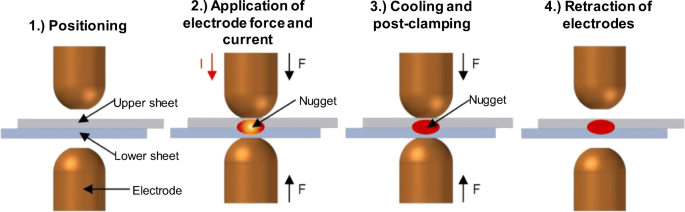

Resistance Spot Welding. Resistance spot welding is used extensively because it is a simple, inexpensive, versatile, and forgiving process. It has been shown to be adaptable to some degree of feedback control.

Precipitation hardening (ph) steels are known to be.

Resistance spot welding is getting significant importance in car, bus and railway bodies etc due to automatic and fast process. What dictates the amount of heat generated in a weld ? At the end of the 19th century, copper electrodes began to be used for resistance spot welding for the first time. Expulsion is an important phenomenon in resistance spot welding. Spot welding resistance spot welding e4education for detail note visit: Resistance spot welding is a process where heat from electrical resistance is used with force and time to weld metallic materials. Improving aluminum resistance spot welding in automotive structures. Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. Spot welding is the type of resistance welding when the thermoelectric heat is generated, sequentially, at a (usually large) number of isolated points spots, where the mating surfaces are. Resistance spot welding (rsw) is regularly used as a successful joining method for a variety of jobs in the automotive and manufacturing fields. 5.1.1 the resistance spot welding process 5.1.2 resistance spot welding equipment 5.1.3 electrodes and electrode maintenance 5.1.4 joint configurations for resistance spot welding 5.1.5.