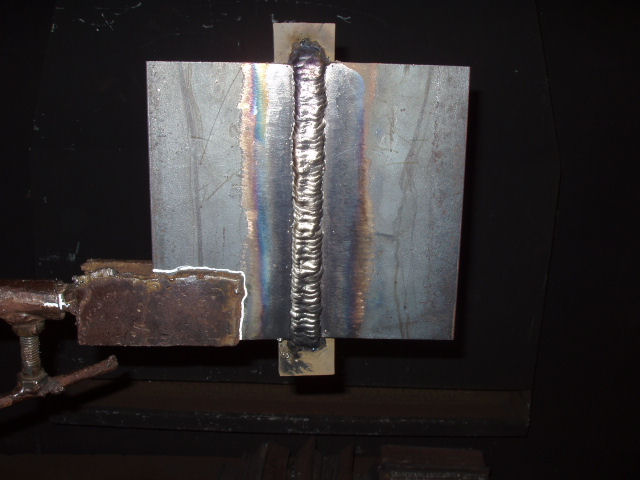

Flux Core Welding. Flux cored arc welding uses heat generated by an electric arc to fuse base metal in the weld joint area. This arc is struck between the metallic workpiece and.

This arc is struck between the metallic workpiece and.

This ultimate guide to flux core welding provides the best flux core welding tips available! Does aluminum flux core welding wire even exist? Although, most people thought of it as an entirely. The reason why it is so important is that the base and filler material can interact with the. Here's a great 14 minutes 20 second video. Welding wire in flux core welding vs mig a youtube video comparing flux core welding and mig. Read on to make your next project the best to can be! Unlike most welding practices, flux core welding does not require a clean joint. Technically the introduction of this process was not new. The welding rod has a flux in the core, a hollow place in the rod, that evaporates under the electrical arc and prevents rapid. Flux core welding, also known as flux core arc welding (fcaw) or tubular electrode welding the usage of flux core welding started in the 1950s.